Unlimited possibilities

Industrial image processing forms the basis for a huge number of positive effects and developments: safety, efficient use of materials, optimal form, function and quality – an overall increase in productivity. All these are the result of high-efficiency image processing.

The possibilities are as varied as our solutions.

Application sorted by industries

- Automobileindustrie

- Food Industry

- Metal Industry

- Electrical industry

- Pharmaceutical Industry

- Overarching

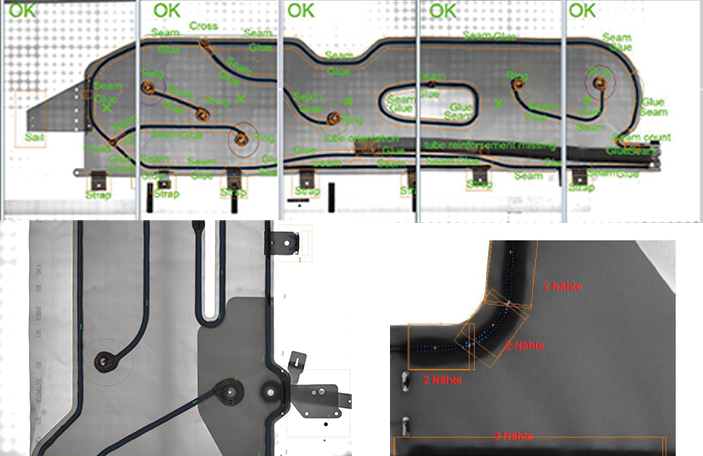

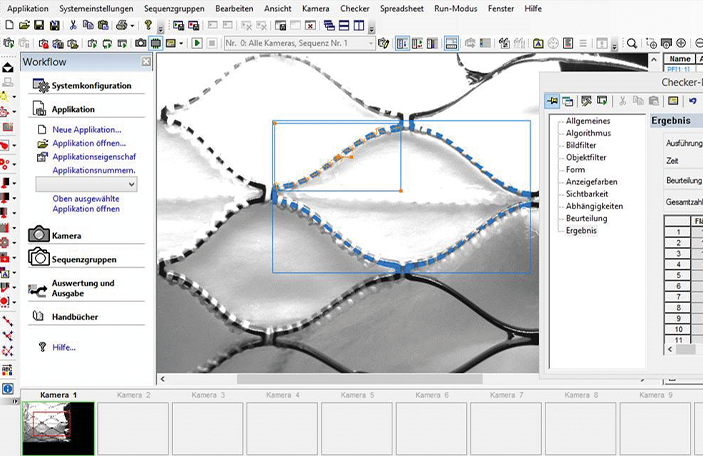

Airbag testing

A special and very easy-to-use algorithm checks the continuous presence of the seams and their correct course within the adhesive mass.

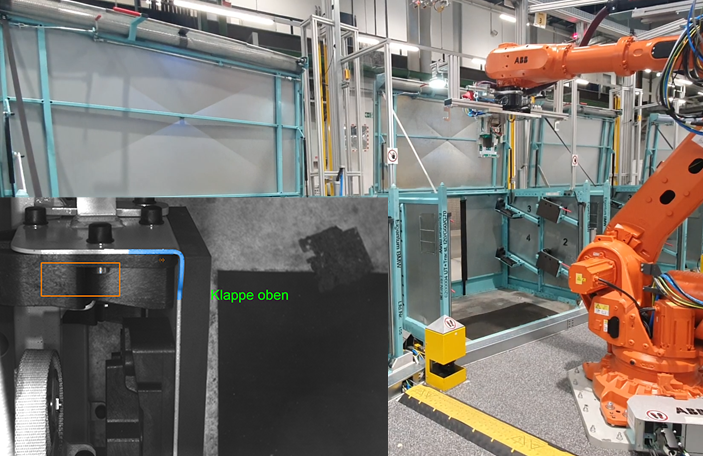

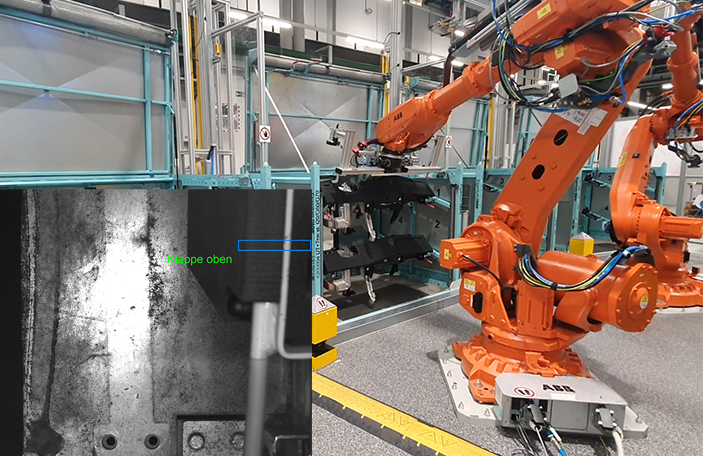

Automatic packing:

- Automatic measurement of the containers and deposit position

- Folding over support points

- Guard fenceless operation

- Containers are transported on and off via AGVs

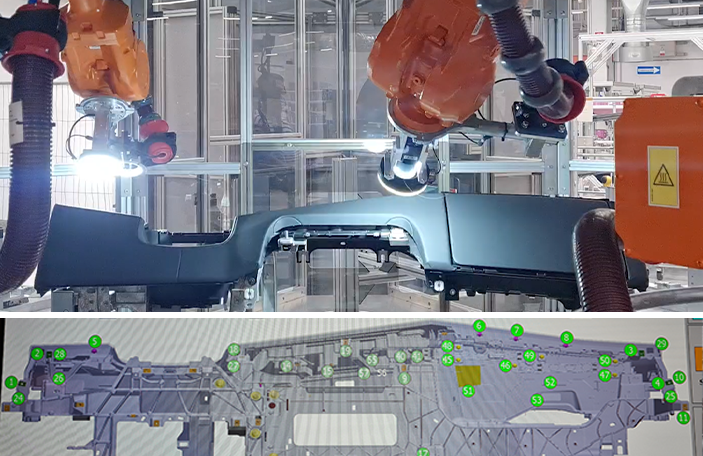

End of Line Testing Dashboard

- Automatic EOL of different I-board types

- 86 Characteristics for presence and correct length

- 2 Measuring tasks

- Total cycle time: 23.5 sec.

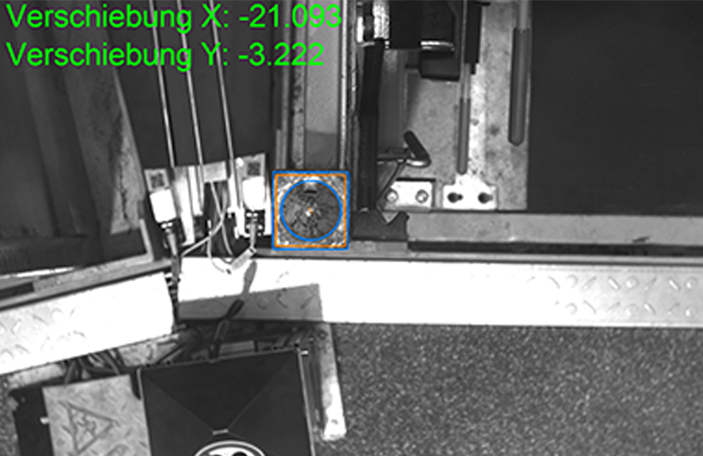

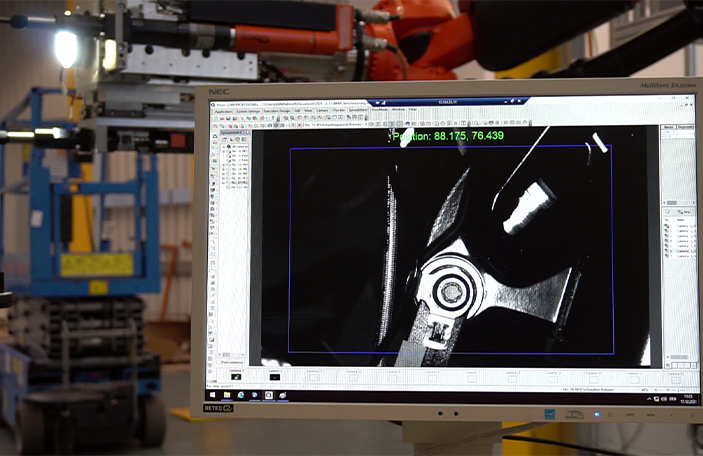

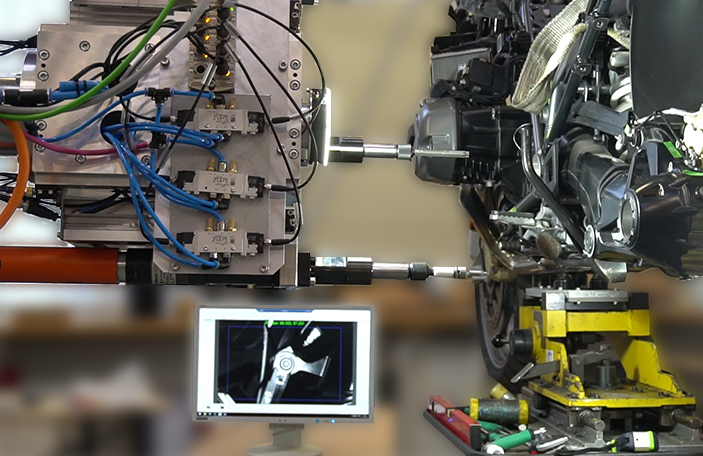

Motorcycle screwing

- Measurement on the motorcycle

- Image acquisition before each screw point

- Transfer of the coordinates to the robot

Cardan shaft error detection

Quality Control

Inspection for paint defects & grease residues

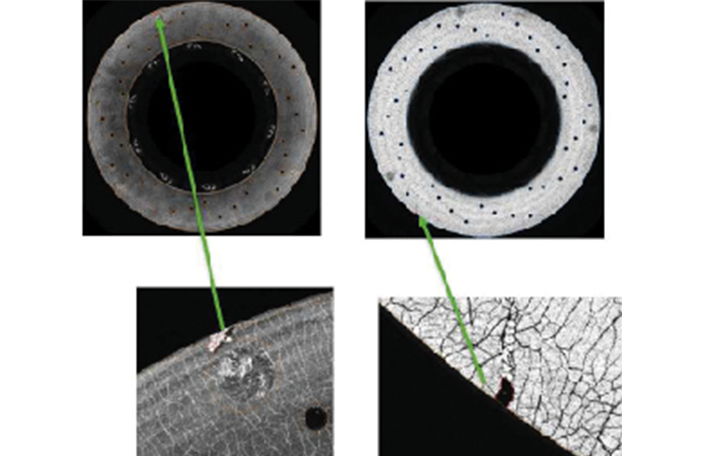

Carbon brake discs

Production monitoring

During the inspection of the bonding surfaces, a brightness detection with the "Extraction Checker" function is used and the component is checked.

Bearing identification

Inline production control

The camera checks the position and quality

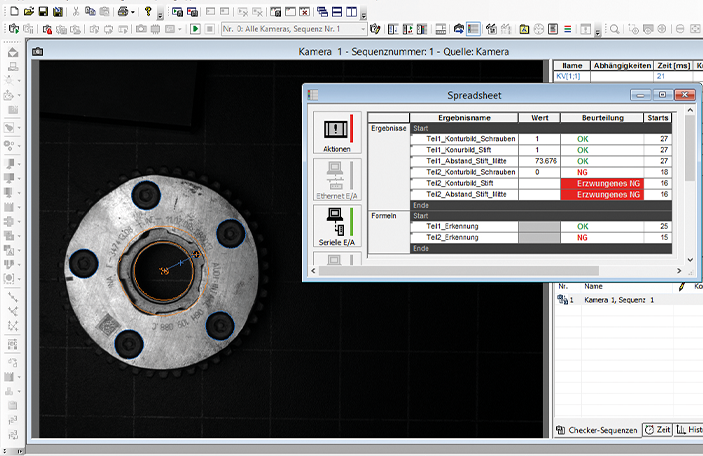

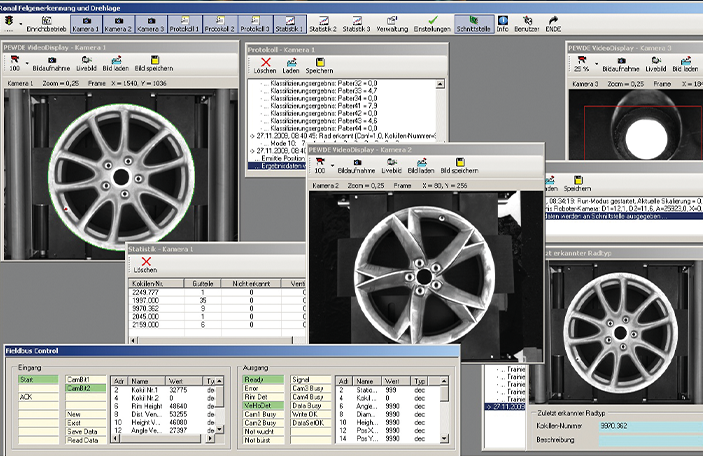

Rim type detection and classification

Measurement and detection of height, width, design and valve hole.

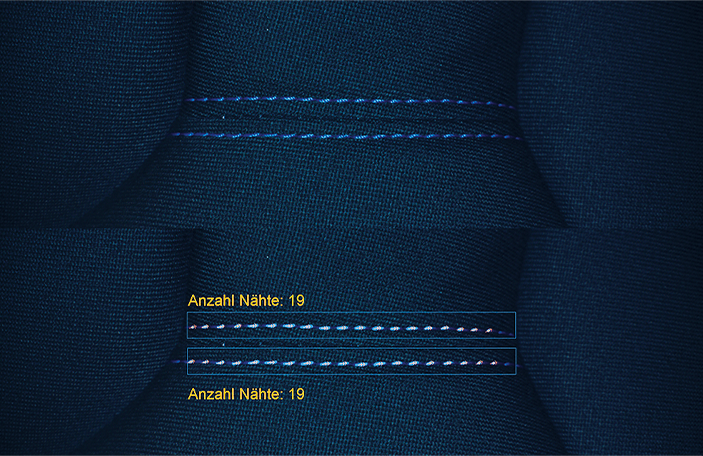

Number & expression of seams

Reliable seam inspection with little contrast or color difference.

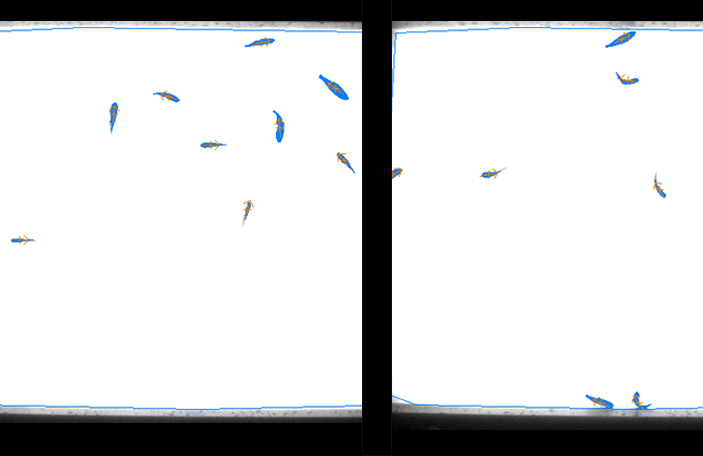

Fish detection

Counting and tracking fish within a tank

Beverage testing

Labels, print image & crown seal inspection

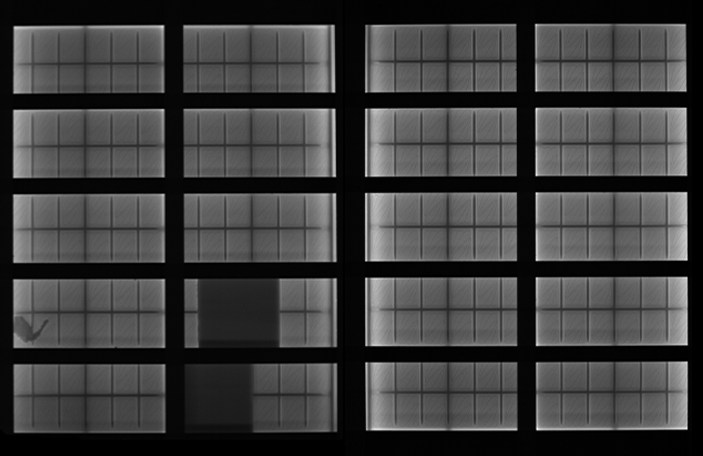

Chocolate bar testing

Defect detection of branded chocolate bars

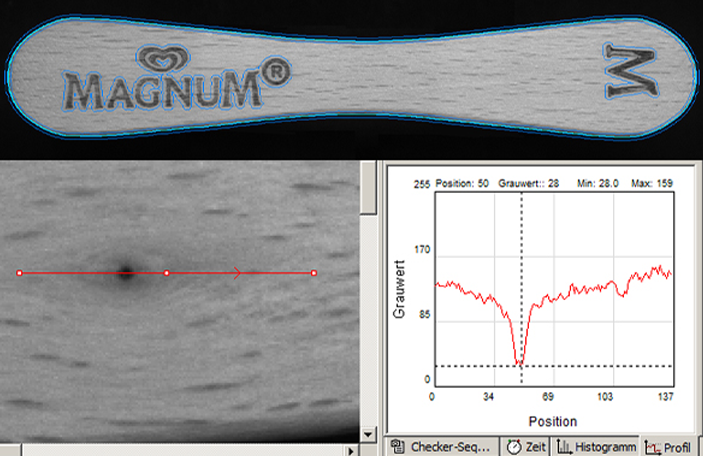

Eissticks-Prüfung

Contour comparison, wood structure check, plain text reading & format check

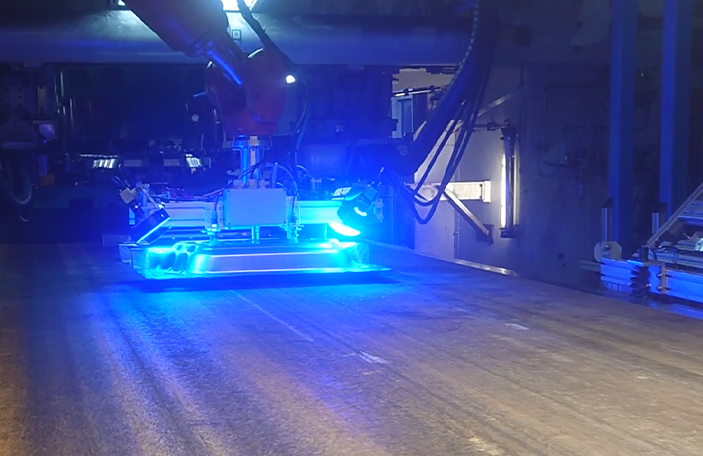

Testing on the transfer press

Testing of components at the end of a transfer press

Check for cracks & constrictions

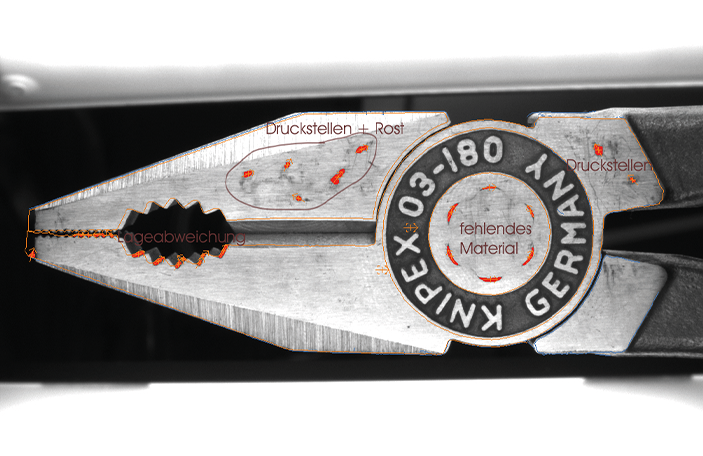

Tool inspection

Checking the quality

Detection of various errors

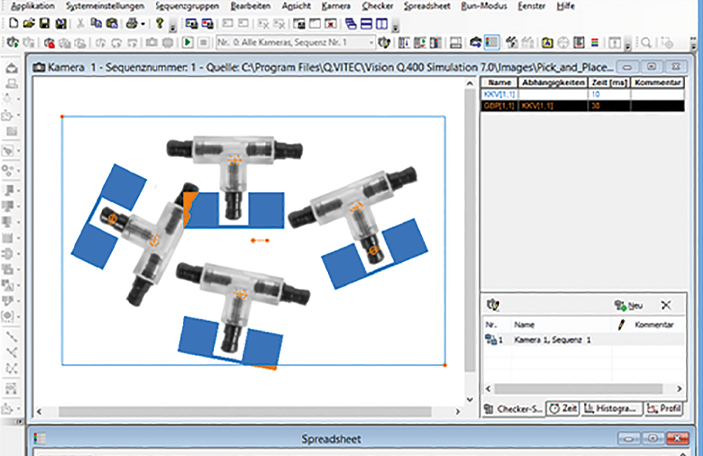

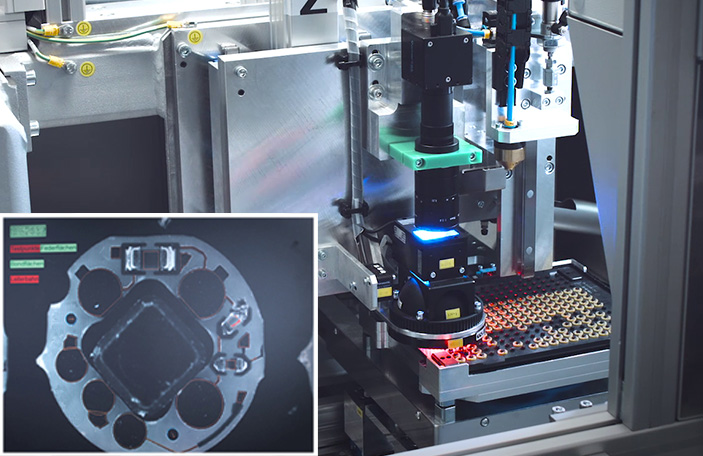

Pick & Place

Contour comparison/feature extraction

To prevent damage to adjacent parts preventis checked for collisions in the freely definable gripping area.

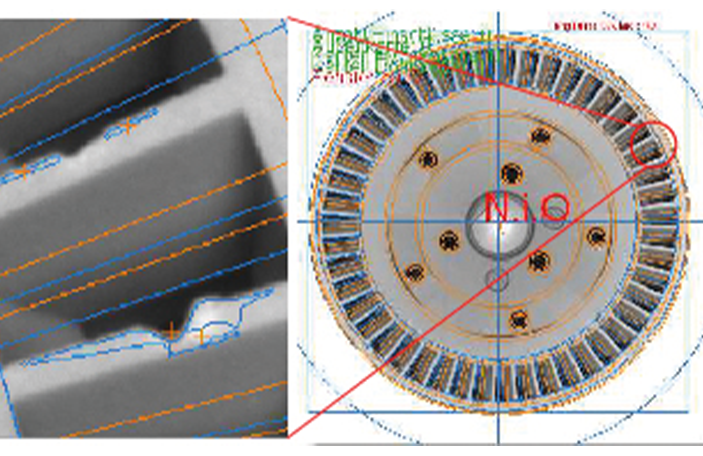

Breakout control

Testing & Surveying

Detection of defects

Breakout control on turbine wheels.

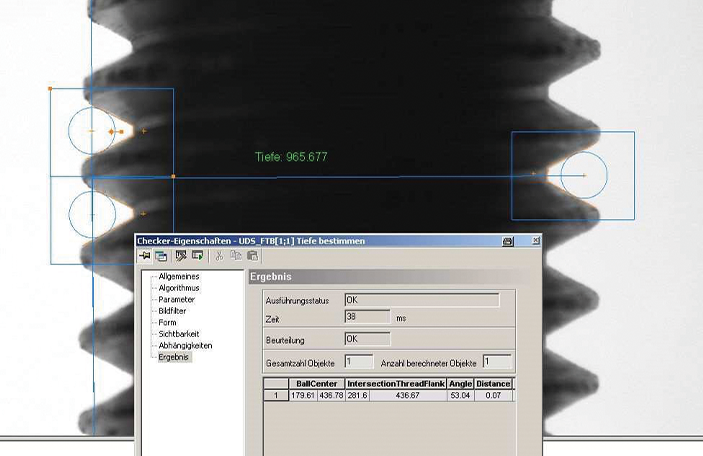

Screw testing

Thread testing

Thread pitch measurement

Applicable for quality or grade purity testing of screws

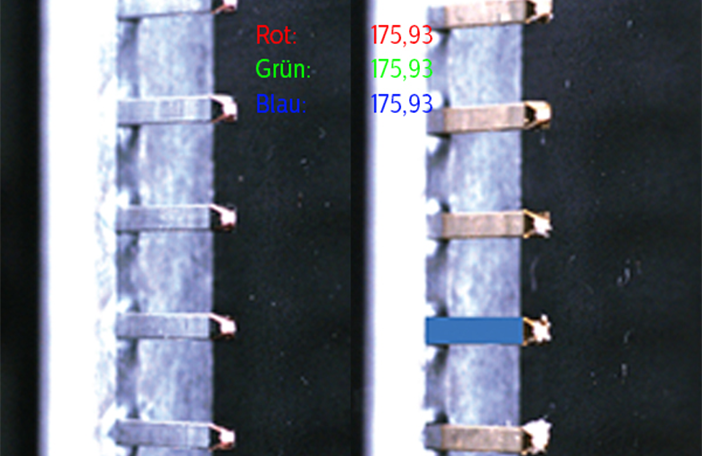

Plug contact test

Monitoring electroplating processes

Coating inspection

Contact check

Measurement and analysis

Detection of defects

Circuit board inspection

Complete surface analysis

Component testing

Checking of bonding surfaces for smallest surface defects, placement control and measurement of the component

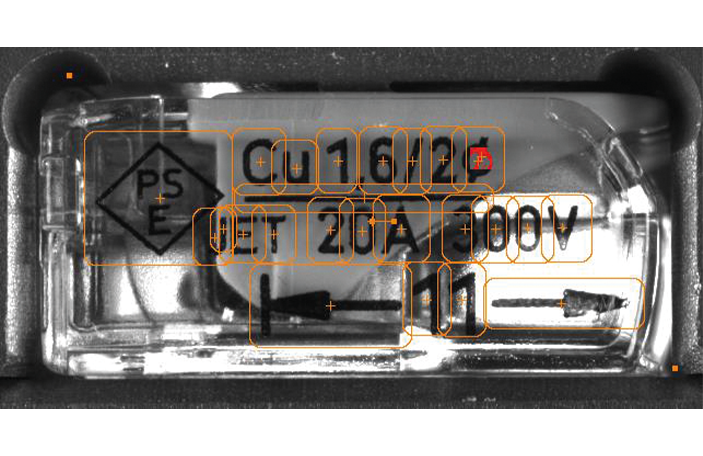

Clamp test

Completeness check

Read plain text

Joining and completeness check on terminals as well as printing check at high speed

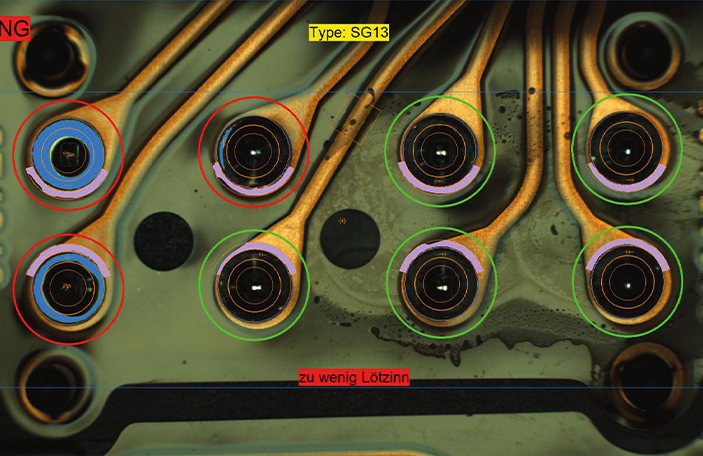

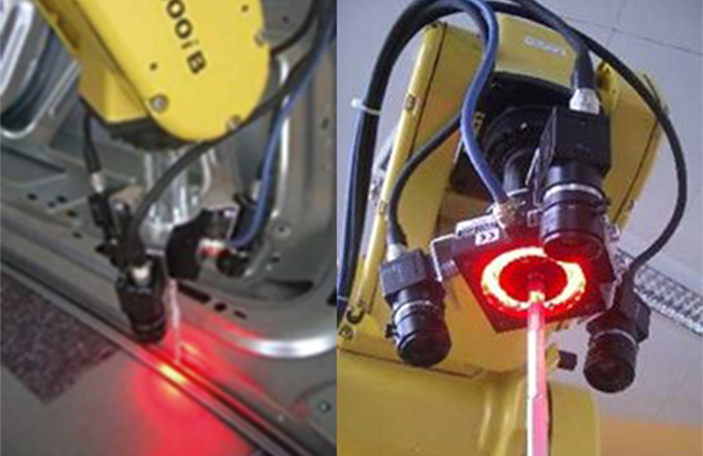

Solder joint inspection

Quality Control

Solder joint monitoring

Robot-guided solder joint inspection on an automotive sensor

Test tube control

Color recognition of the caps, as well as fill level control and bar code reading

Aortic valve testing

Seam control

Checking manually created seams for the prescribed number of stitches within an area

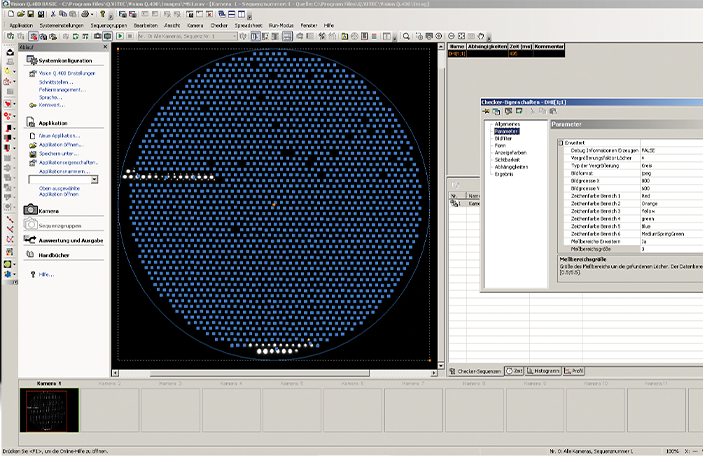

Membrane testing

Quality inspection (membrane drill hole inspection)

Monitoring of the micro-holes for size and continuity

Fill level control

Fluid testing

Detection of filling levels

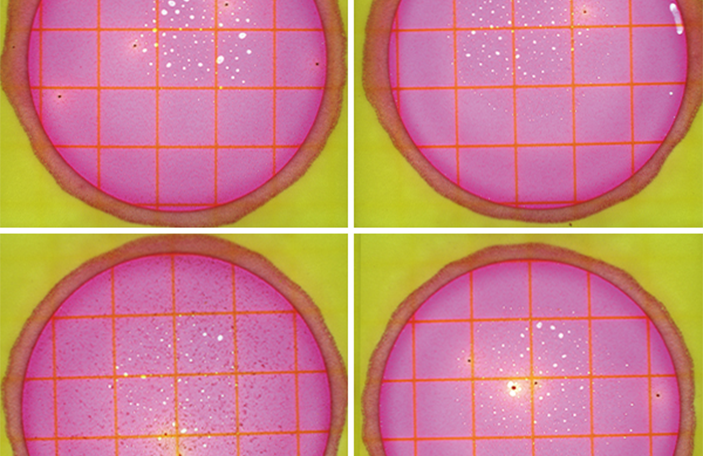

Bacteria testing

Monitoring of bacteria cultures

Counting bacteria

Testing of gaskets

Error Detection

Check damage to the sealing surface

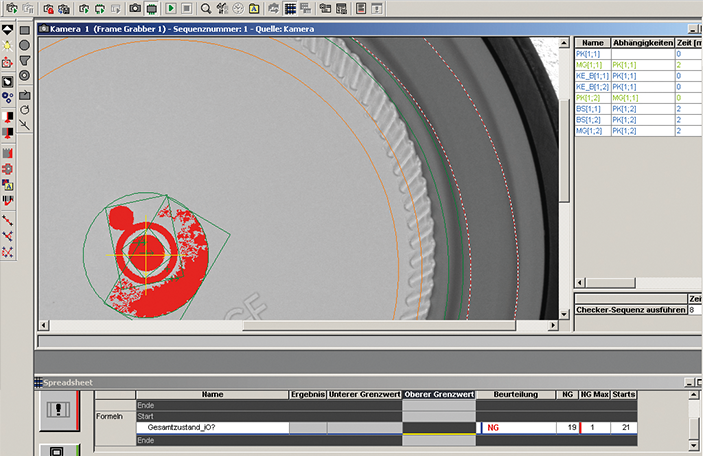

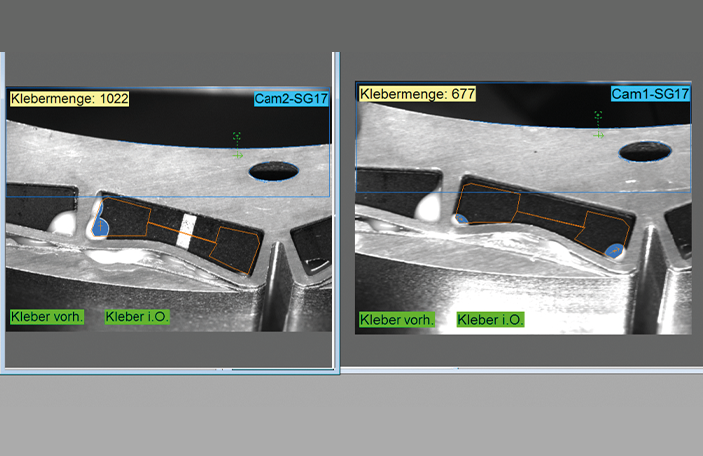

Adhesive bead inspection

adhesive & weld seam testing

Quality check

Robot-guided 3D adhesive bead inspection in the automotive sector

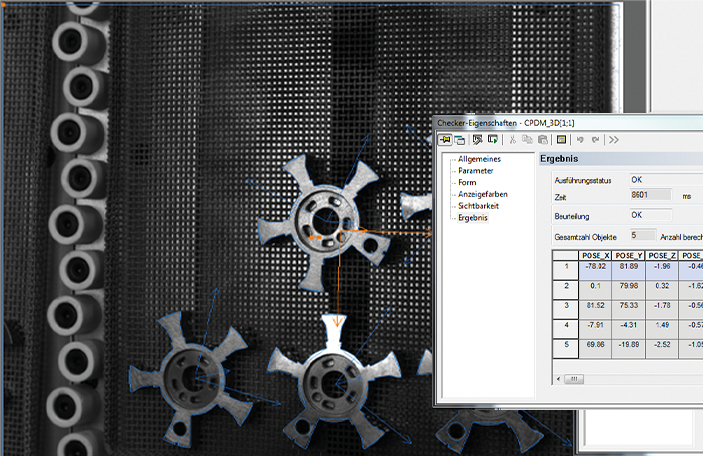

Depalletizing

Bearing identification

3D gripping position for robots

Automatic 3D gripper position detection for (de)palletizing of sintered metal parts

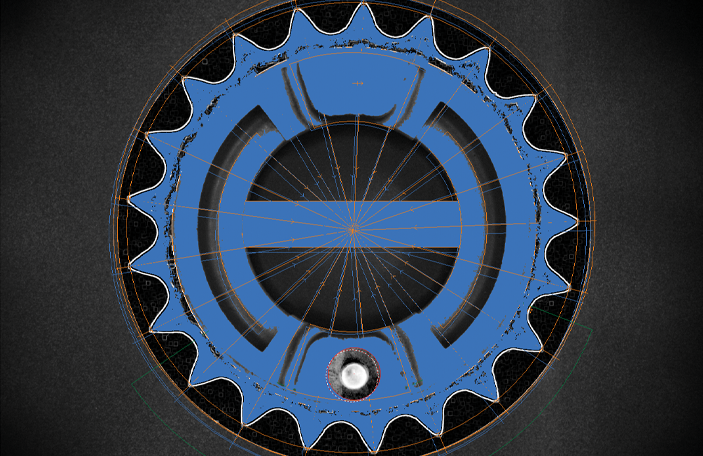

Component measurement

Dimensional accuracy & contour inspection (gear wheel measurement)

Surveying & Geometric Analysis

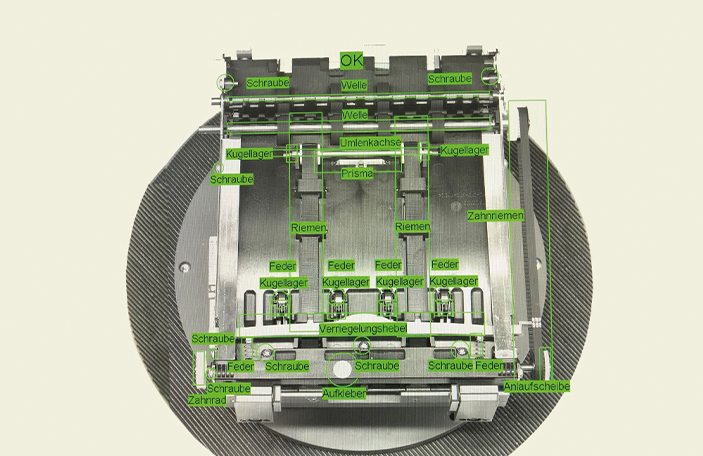

Assembly monitoring

Completeness check

Assembly monitoring of manual workstations for completeness control. Later hidden components are automatically checked for completeness during assembly.

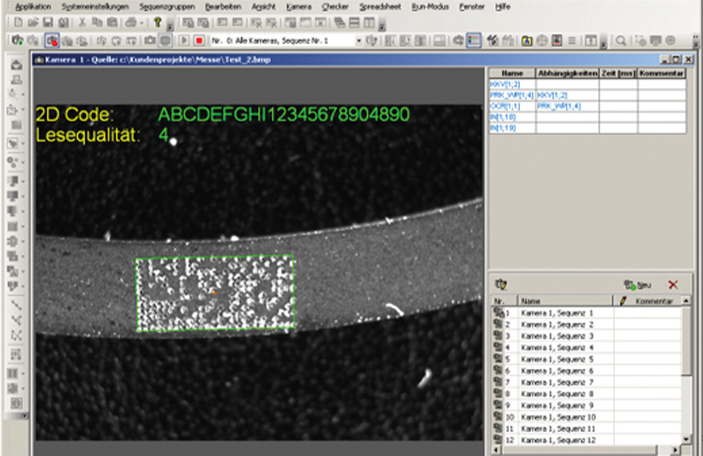

Code evaluation

Code reading (piston rings)

Code size: 2mm x 5mm testable

Reading matrix codes and checking marking quality according to AIM DPM-1-2006

Runtime monitoring

Fill level detection

Automatic metering quantity determination during metering to determine the optimum adhesive quantity

Not found what you were looking for?

Contact us, together we will find the perfect solution for your project.

ManagementPurchase / Sale

Markus PrausHead of Sales

+49 (0)5031 – 949 43-20

info@qvitec.de

+49 (0)171 – 170 20 53

m.praus@qvitec.de