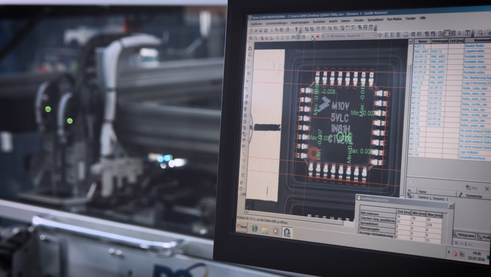

Testing functions

Vision Q.400 has highly efficient tools. They can be used to parameterise inspections and detection, with Vision Q.400 optionally working with images from grey-scale or colour cameras.

High precision measurement, e.g. of distances, angles, radii, diameters and surfaces. Depending on the boundary conditions (camera optics, lighting), a repeatability of 1/20 pixels or a few micrometers is feasible.

High precision measurement, e.g. of distances, angles, radii, diameters and surfaces. Depending on the boundary conditions (camera optics, lighting), a repeatability of 1/20 pixels or a few micrometers is feasible.

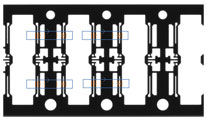

By identifying missing or unwanted details in the camera image, it is easy to perform a component presence check, and to classify or sort objects.

By identifying missing or unwanted details in the camera image, it is easy to perform a component presence check, and to classify or sort objects.

A variety of procedures enable the recognition of patterns or structures. A particularly elegant approach is contour comparison, which can even identify overlapping characteristics, or characteristics that vary in size and shape.

A variety of procedures enable the recognition of patterns or structures. A particularly elegant approach is contour comparison, which can even identify overlapping characteristics, or characteristics that vary in size and shape.

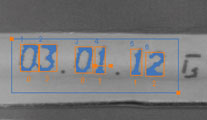

The algorithm employed here recognises characters based on fonts it has been trained to identify. It is possible to achieve extremely high recognition rates, even in hard to read characters like those of dot matrix printing or "direct part marking" on metal.

The algorithm employed here recognises characters based on fonts it has been trained to identify. It is possible to achieve extremely high recognition rates, even in hard to read characters like those of dot matrix printing or "direct part marking" on metal.

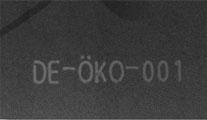

Vision Q.400 can read numerous barcodes and 2D codes, even under critical conditions. Codes marked directly on the component (DPM) are also reliably recognised. Optionally, code quality is determined and output in accordance with ISO/IEC 15415 or AIM DPM-1-2006.

Vision Q.400 can read numerous barcodes and 2D codes, even under critical conditions. Codes marked directly on the component (DPM) are also reliably recognised. Optionally, code quality is determined and output in accordance with ISO/IEC 15415 or AIM DPM-1-2006.

A secondary action of object recognition is also the position information (x, y, angle) of the identified objects. This data can be used e.g. for Pick & Place tasks sent to a handling robot or in order to perform assembly inspections.

Identifying extremely small defects or imperfections over relatively large surface areas is one of the most demanding testing tasks. Vision Q.400 offers several efficient and rapid solutions to this end.

Identifying extremely small defects or imperfections over relatively large surface areas is one of the most demanding testing tasks. Vision Q.400 offers several efficient and rapid solutions to this end.

It is not always possible to perform optical imaging on a test object, and in some cases disruptive boundary conditions can lead to unsuitable image quality. Various algorithms in Vision Q.400 permit the enhancement and pre-processing of such images before they are subjected to the actual inspection process.

It is not always possible to perform optical imaging on a test object, and in some cases disruptive boundary conditions can lead to unsuitable image quality. Various algorithms in Vision Q.400 permit the enhancement and pre-processing of such images before they are subjected to the actual inspection process.